L500LA | L500LMA

The CNC Turning Center L500 Series, designed by Hyundai WIA with years of expertise and the latest technology, is a Turning Center that maximizes productivity and performance.

- Box guideways on all axis ensuring high rigidity in heavy cutting conditions

- Absolute motor encoder in all axes

- Head stock designed to minimize thermal distortion

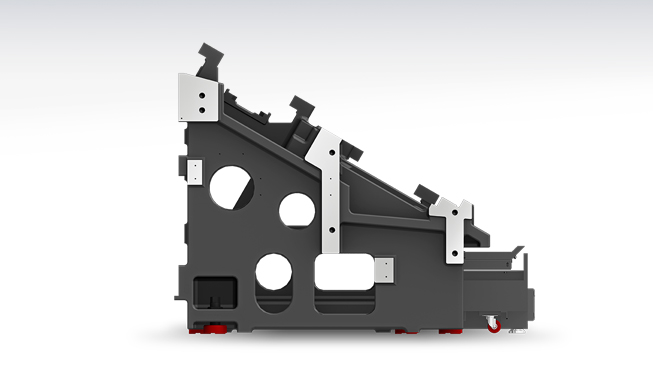

- 30° Slant Bed Structure

High Precision & Rigidity, One-Piece Bed Structure

Designed with FEM(Finite Element Method) analysis, the L500 Series

has bed structure of 30° slope to improve machining accuracy and

cutting ability. In addition, increased bed installation area improves vibration absorption and machining stability.

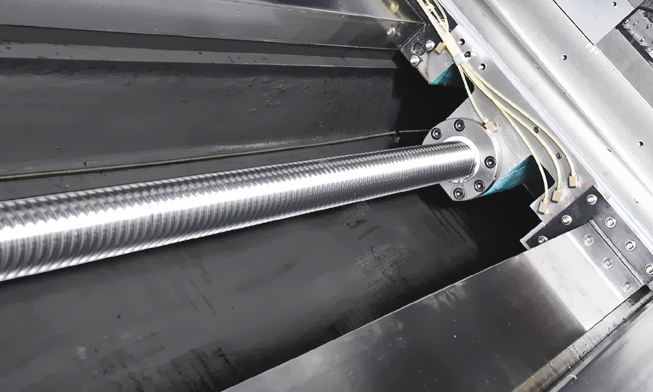

Guideway

Box Guideway

All axes of L400MC CNC turning centers Series are designed with Box Guideways for better travel ability. Box Guideways show great performance in offsetting vibrations caused by heavy duty cutting.

X-Axis Guideway

Expanded guideways for high precision and enhanced heavy duty cutting ability.

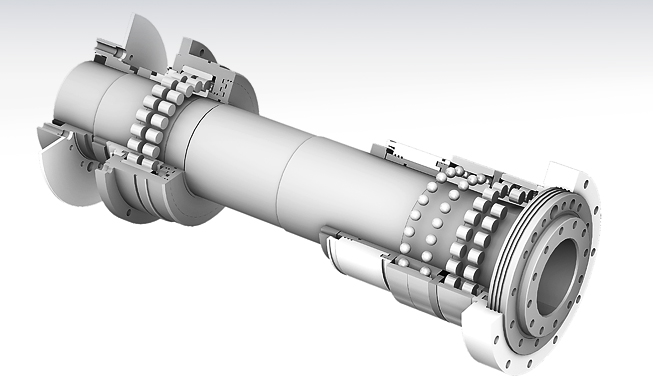

Main Spindle

Spindle Ideal for Heavy Cutting

To accomplish advanced stability during heavy duty cutting, a combination of P4 double cylindrical roller bearings and angular bearings are adopted.

The double locking device separates the spindle bearing and pulley to prevent a decrease in spindle bearing pretension during interrupted cutting, heavy duty cutting, chuck cylinder operations, and by belt pulley tension.

2 Step Gear Box

A two-step driving method is applied inside the main spindle as standard on non mill turrets. It provides powerful torque at low speeds and stable rotation at high speeds.

C-Axis Control (L500LMA)

The C-axis is capable of 0.001° control when milling turret is applied. Machining capability is strengthened with turning and milling operations.

Big bore spindle (L400C Series)

The big bore spindle of Ø181mm (7.1″) provides excellent performance during pipe machining. Also, spindle torque of 2,705N・m(1,995.1lbf・ft) is optimal for heavy duty cutting.

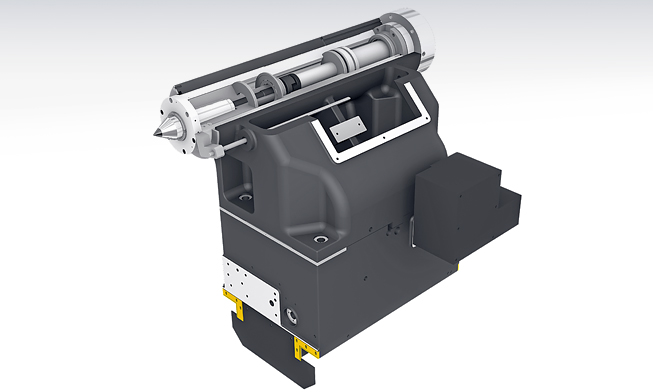

Built-In Tail Stock

The built-in tail stock ensures high accuracy even during heavy duty cutting and can be controlled automatically or manually.

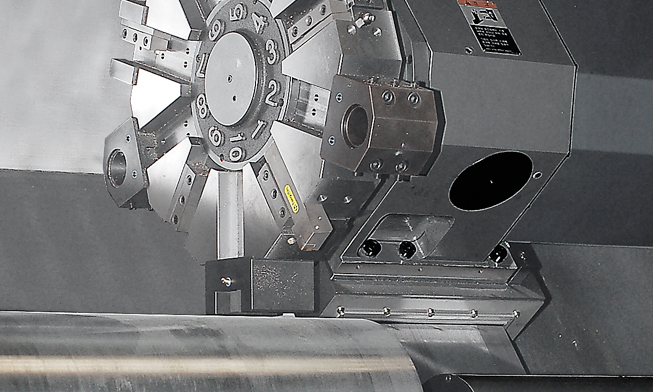

Turret

Servo Turret

The L500 Series apply an AC Servo Motor to enhance machining reliability. Also, split accuracy is improved by using 3-piece couplings.

Powerful hydraulic tool clamping system minimizes tool tip displacement caused by workload.

High Pressure Coolant

Turret is designed to utilize 70 bar high pressure coolant and it shows optimum performance in machining difficult-to-cut material.

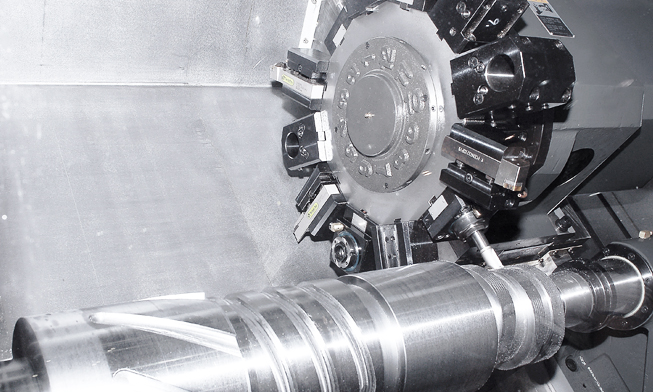

BMT75 Mill Turret

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

L500 Series high precision CNC turning centers

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Steady Rest

For long parts, such as shafts, the steady rest increases rigidity and minimizes vibration.

Rear Chuck

The rear chuck option enables long products such as long shaft or pipes to be processed in a stable condition.

Technical Specifications L500LA

| Max Turning Dia [mm] | 720 |

| Max Turning Length [mm] | 2,109 |

| Driving Method | Gear |

| Chuck Size [inch/mm] | 21″/533,4 |

| Spindle RPM [rot/min] | 1,500 |

| Spindle Output [kW] | 45/37 |

| Spindle Torque [Nm] | 4,112/3,382 |

| Travel (X,Y) [mm] | 400/2,210 |

| Rapid Travel [m/min] | 20/18 |

| Slide Type | BOX |

| No. of Tools | 10 |

| Tool Size (turning/milling) [mm] | 32/80 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications L500LMA

| Max Turning Dia [mm] | 690 |

| Max Turning Length [mm] | 2,100 |

| Driving Method | Gear |

| Chuck Size [inch/mm] | 21″/533,4 |

| Spindle RPM [rot/min] | 1,500 |

| Spindle Output [kW] | 45/37 |

| Spindle Torque [Nm] | 2,990/2,459 |

| Travel (X,Y) [mm] | 400/2,210 |

| Rapid Travel [m/min] | 20/18 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 32/63 |

| Milling Tool Speed [rot/min] | 4,000 |