L4000 | L4000M | L4000C | L4000MC

The CNC Turning Center L4000 series, designed by Hyundai WIA with years of expertise and the latest technology, is a Turning Center that maximizes productivity and performance.

- Spindle Ideal for Heavy Cutting

- 40% Improvement in torque compared to the previous model

- Improvement in machining performance with application of Bzi sensor as standard

- Rigidity secured through box guideways

- Increased contact area between the saddle and cross-slide

- Increased swing for machining large workpieces

- Applying an AC Servo Motor to enhance machining reliability

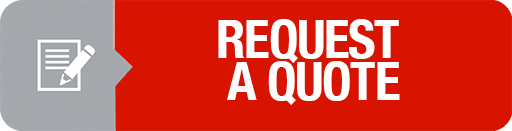

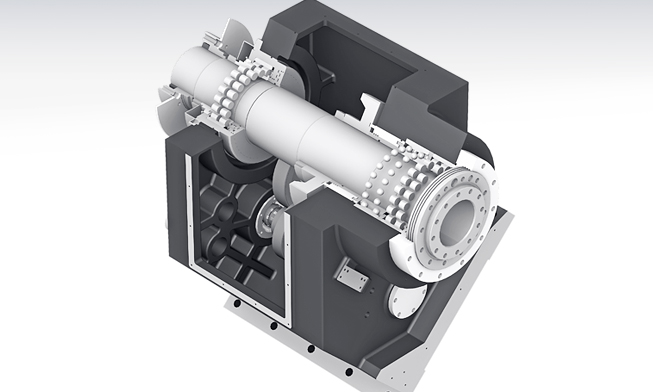

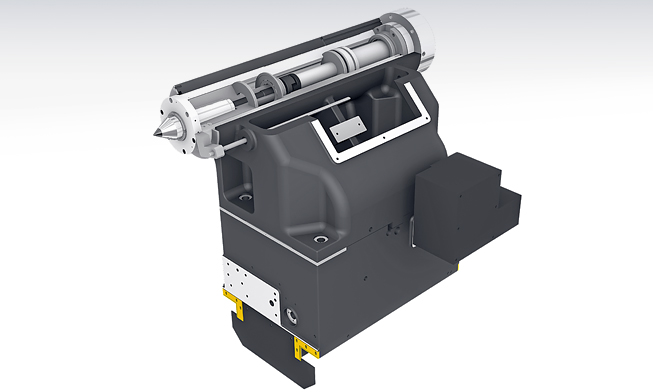

High Precision & Rigidity, One-Piece Structure

The L4000 Series features a 45° slant bed design which is developed through finite element analysis (FEA) to absorb vibration and minimize thermal displacement so as to maintain high stability.

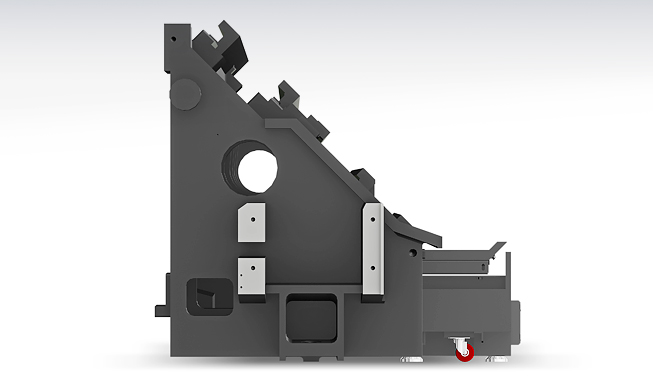

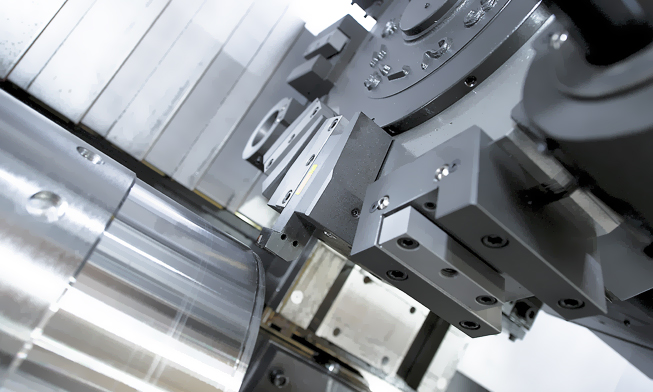

Guideway

Box Guideway

With the mounting of box guideways on all axes, the machine offers excellent vibration absorption even against during heavy-duty cutting, enabling high-quality machining.

Improved saddle rigidity

The contact area between the saddle and the cross-slide has been increased for high rigidity.

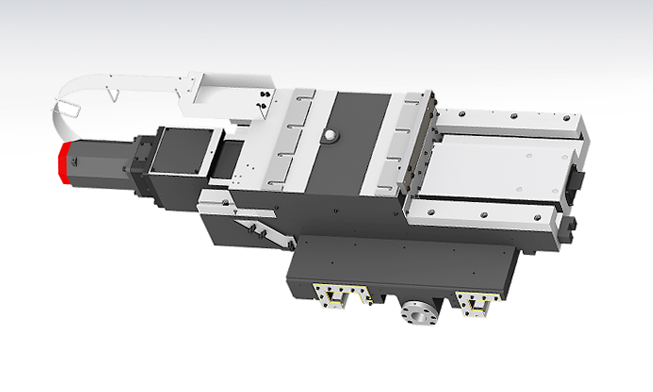

Ball Screw

Large diameter ball screws with preloading prevent deformation due to heat. Also double-anchor suppport method improves rigidity.

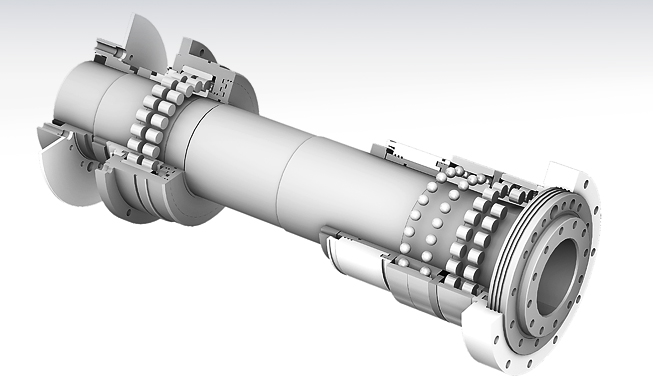

Main Spindle

Spindle Ideal for Heavy Cutting

High-precision double-row cylindrical roller bearings and angular contact bearings offer increasement in rigidity of the spindle. In addition, the two- step gearbox guarantees strong torque at low speed and stable machining capability at high speed.

Spindle Gear Box

Gear shift of spindle provide stability and high torque during low speed.

C-Axis Control (‘M’ Type)

The C-axis is capable of 0.001° control when milling turret is applied. Machining capability is strengthened with turning and milling operations.

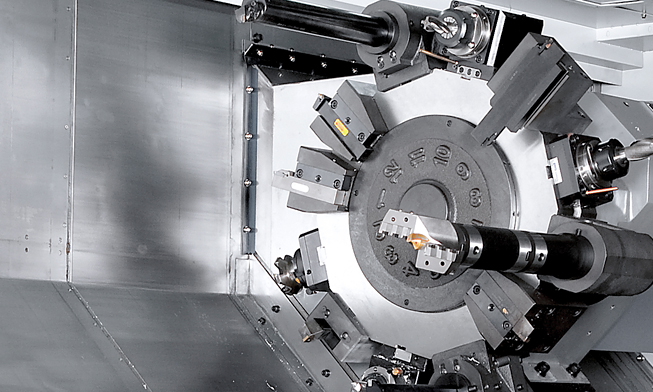

Turret

Standard Turret

The turret of L4000 series is applied with high performance AC servo motor, improving machining reliability. 3-piece coupling shows excellent performance in indexing. Powerful hydraulic tool clamping minimizes tool tip deviation caused by load.

70 bar High Pressure Coolant [option]

Turret is designed to utilize 70 bar high pressure coolant and it shows optimum performance in machining difficult-to-cut material.

BMT75 Mill Turret (‘M’ Type)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder.

Various Devices for User Friendly / Options

High-performance Tail Stock

The large tailstock of Ø120mm is applied for high rigidity. The tailstock provides extra support with 120mm (4.7′′)travel. (MT#5 Built-in Tail Stock : Option)

Steady Rest [option]

For long parts, such as shafts, the steady rest increases rigidity and minimizes vibration.

Automatic Q-Setter

Cutting tools are calibrated quickly and accurately with the addition of a q-setter. Each tool tip is touched off manually using a sensor that inputs the position automatically.

Linear Scale

Linear scales increase positioning accuracy and reduce distortion caused by thermal growth, thus ensuring a more accurate finished part.

Long Boring Tool holder

When using long boring tool holder, deeper inner diameter machining is possible, enabling faster and more precise machining.

Technical Specifications L4000

| Max Turning Dia [mm] | 570 |

| Max Turning Length [mm] | 1,043 |

| Driving Method | Gear |

| Chuck Size [inch/mm] | 15″/381 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 35 |

| Spindle Torque [Nm] | 2,450 |

| Travel (X,Y) [mm] | 330/1,105 |

| Rapid Travel [m/min] | 16/20 |

| Slide Type | BOX |

| No. of Tools | 10 |

| Tool Size (turning/milling) [mm] | 32/60 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications L4000M

| Max Turning Dia [mm] | 570 |

| Max Turning Length [mm] | 958 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 15″/381 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 30 |

| Spindle Torque [Nm] | 1,611 |

| Travel (X,Y) [mm] | 330/1,105 |

| Rapid Travel [m/min] | 16/20 |

| Slide Type | BOX |

| No. of Tools | 12 |

| Tool Size (turning/milling) [mm] | 32/60 |

| Milling Tool Speed [rot/min] | 4,000 |

Technical Specifications L4000C

| Max Turning Dia [mm] | 570 |

| Max Turning Length [mm] | 1,025 |

| Driving Method | Gear |

| Chuck Size [inch/mm] | 21″/533.4 |

| Spindle RPM [rot/min] | 1,500 |

| Spindle Output [kW] | 37 |

| Spindle Torque [Nm] | 3,378 |

| Travel (X,Y) [mm] | 330/1,105 |

| Rapid Travel [m/min] | 16/20 |

| Slide Type | BOX |

| No. of Tools | 10 |

| Tool Size (turning/milling) [mm] | 32/60 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications L4000MC

| Max Turning Dia [mm] | 570 |

| Max Turning Length [mm] | 940 |

| Driving Method | Gear |

| Chuck Size [inch/mm] | 21″/533.4 |

| Spindle RPM [rot/min] | 1,500 |

| Spindle Output [kW] | 37 |

| Spindle Torque [Nm] | 1,812 |

| Travel (X,Y) [mm] | 330/1,105 |

| Rapid Travel [m/min] | 16/20 |

| Slide Type | BOX |

| No. of Tools | 10 |

| Tool Size (turning/milling) [mm] | 32/60 |

| Milling Tool Speed [rot/min] | 4,000 |