KF6700M

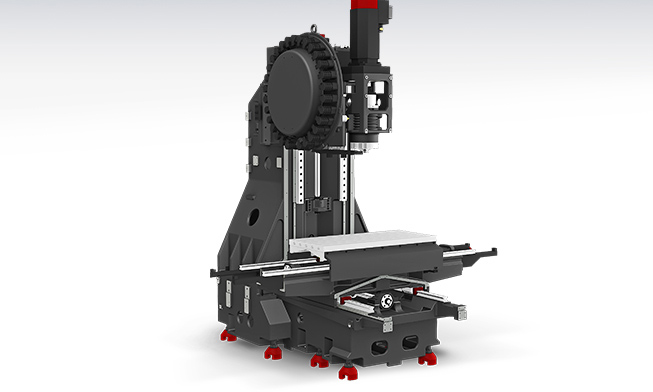

KF6700M Vertical Mold Machining Center is a 3-axis machine with rigid guideways with high mass and cutting speed for the mold industry.

- Built-in 20,000rpm spindle for a high-quality mold processing

- Mold packages for optimum mold manufacturing

- High-speed roller type LM guide and ball screw.

- The KF6700M Vertical Mold Machining have Enhanced chip processing capabilities by applying the upper-type conveyor

State-of-the-art Vertical Machining Center with High-speed and large work space

High-Precision Structure

Optimal Structural Analysis

KF-II Series is designed to have optimal structure through Hyundai WIA’s unique structural analysis. In particular, enhancement of bed and column’s rigidity makes excellent performance even in heavy duty cutting.

One Piece High Column (Direct Sp.)

One piece high column is provided as an option up to z-axis hegiht. This option helps to process bigger products such as rack housing.

Guideways

High-Speed Roller LM Guideway

Linear roller guideways are applied to reduce non-cutting time and bring high rigidity. Each axis is directly connected to a highly reliable digital servo motor to provide high rigidity and minimal thermal displacement.

Improvement in Slide Cover

The increased slope of slide cover makes chip disposal easier and minimizes slide cover breakage.

Improvement in Slide Cover

The increased slope of slide cover makes chip disposal easier and minimizes slide cover breakage.

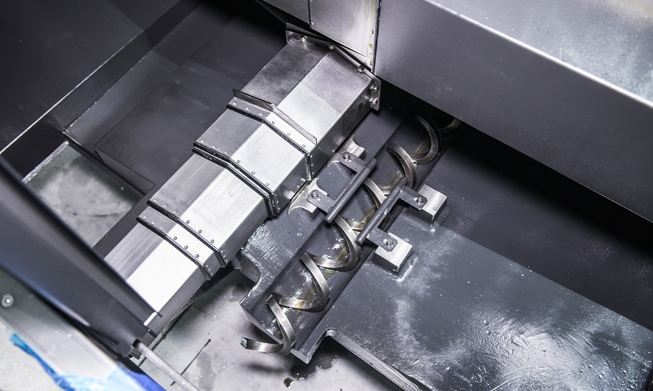

Double Anchored Ball Screw

The pretensioned ball screw minimizes the expansion and contraction according to the heat and further reinforces the rigidity by the double anchor support method. In addition, the coupling of the ballscrews and the highly reliable digital servo motors are connected by metal plate couplings, to reduce coupling breakage and backlash.

Increase in Durability of Z-axis ball screw

Lifetime of the bearing has been greatly increased by optimizing the spindle structure and lubrication method.

Nut cooling ball srew

Nut cooling ball screws on all axes decrease thermal displacement which enhances precision machining ability. (KF5600M/6700M)

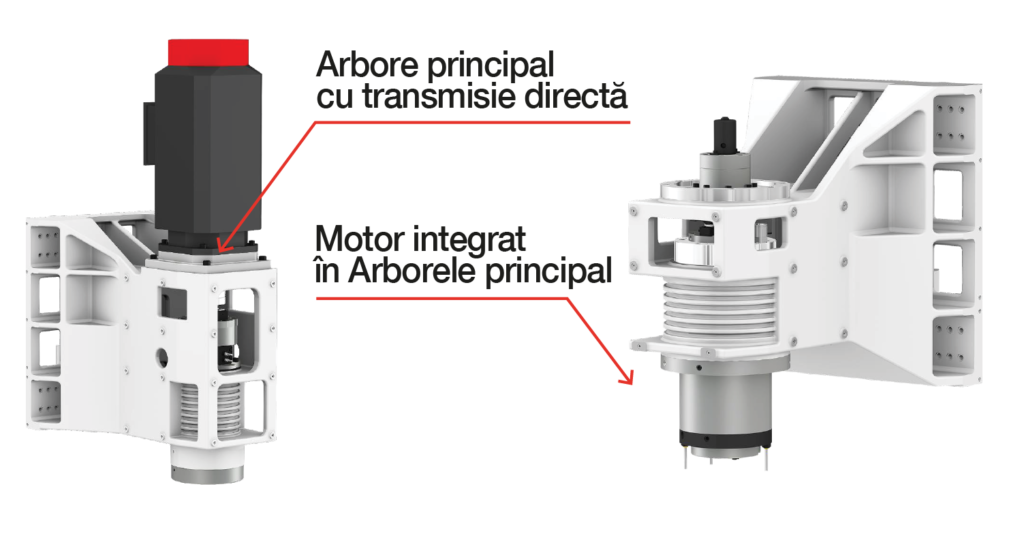

Spindle

Built-in Spindle (KF5600M/6700M)

The 20,000rpm built-in spindle can minimize vibration transmitted to the spindle. It allows excellent machining performance in mold and high-precision products.

Spindle Cooling (Over 10,000 rpm Std.)

The spindle cooling system minimizes thermal displacement which can happen during lengthy machining operations, and offers continued accuracy based on the thermal stability.

Through Spindle Coolant (20/30/70 bar)

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time. The improved quality of rotary joint prevents oil leakage.

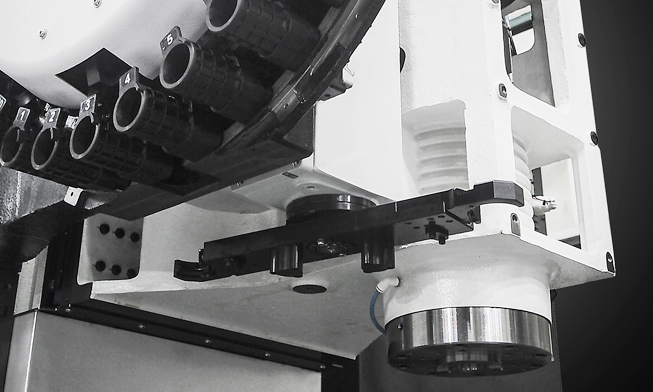

ATC & Magazine

High Speed ATC

Position control through twin arm ATC on servo motors has been

improved drastically. In addition, tool exchanging has become

easier, reducing specific cutting time tremendously. Position control on the Twin Arm ATC has improved drastically. The twin arm ATC enables faster tool change and increased productivity.

Magazine

The tool magazine holds 30 tools as standard and 40 tools as an

option. Due to the wider selection of tools and the random tool

selection method, tool change time has improved.

Chip disposal solution & coolant unit

Interior Screw Chip Conveyor (Forward / Backward Rotation Function)

Dual screw type chip conveyors are located at each side of the bed which makes it convenient to remove chips. The interior screw and the chip conveyor operate at the same time and can be controlled separately at the time of prior consultation.

(Three screws for rear-type conveyor: 2 sides + 1 front). Furthermore, chip disposal capability significantly has been improved due to optional bed-flushing coolant.

NC Rotary table & hydraulic supply unit

Various shapes of products can be processed when using NC Rotary Table. In addition, 100 bar of high pressure hydraulic unit for the fixture increases the tightening power of the teeth.

Technical Specifications KF6700M

| Table Size [mm] | 1500×670 |

| Max. Load Capacity [kg] | 1,300 |

| Spindle Driving Method | Built in |

| Spindle Taper | BBT40 |

| Spindle RPM [r/min] | 20,000 |

| Spindle Power [kW] | 22/18.5 |

| Spindle Torque [Nm] | 98/80 |

| Travel(X/Y/Z) mm | 1300/670/635 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 36/36/30 |

| Slide Type | LM |

| No. of Tools | 30 |

| Tool Change Time (Chip To Chip) [sec] | 3.2 |