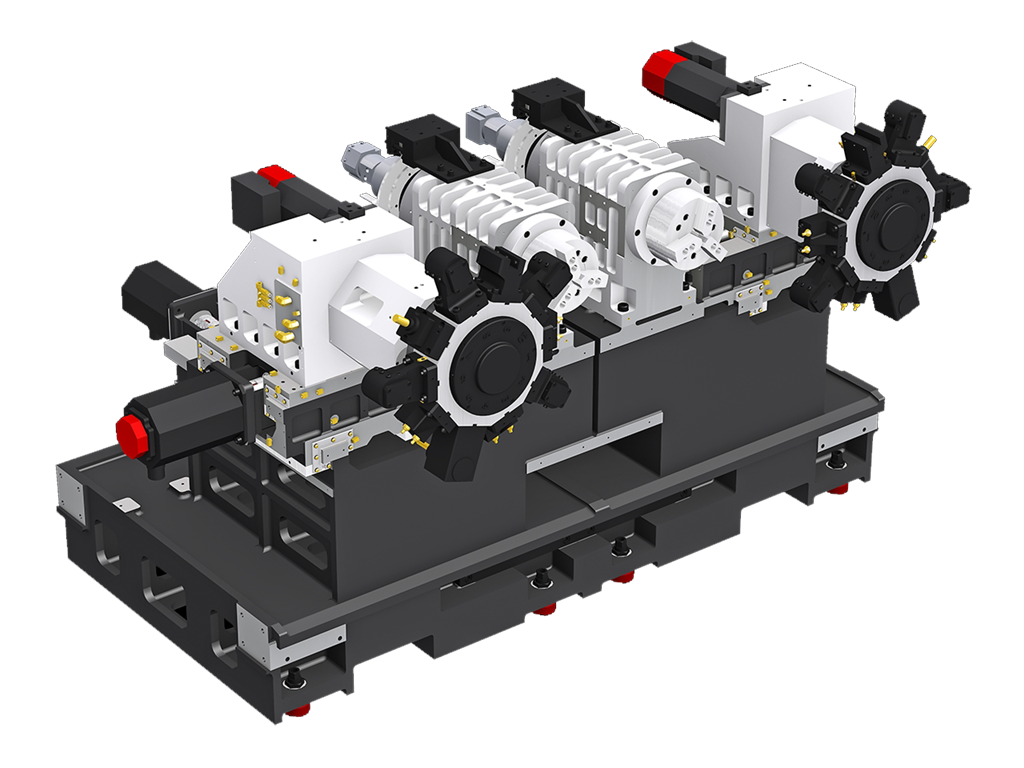

LF2600 II | LF2600Quick II | LF2600M II | LF2600MQuick II

LF2600II front turning center with two universals offers high precision and excellent cutting performance.

- Increased rigidity by improving Z-axis structure

- Selection between roller LM guide and box guide way

- Stable unit composition with minimized thermal deformation

- LF2600II front turning center have Various types of gantry loader ensure effective & flexible automation

- A pleasant working environment by improving chip disposal ability

- Enhanced convenience by applying Fanuc’s latest controller

Optimized design CNC turning center with double front loading

Separate frame structure of high precision

The LF2100 / 2600 series is designed as a separate frame structure, thus reducing thermal deformation and vibration, ensuring a stable cutting capacity.

Z-axis Structure

Prevent sagging of the turret by reducing the protruded parts of the headstock by changing the structure of the Z-axis, and allow for high-precision machining of the product by increasing rigidity.

Guideway

Roller LM Guide / Box Guide

The transfer axis of LF-II Series give options for roller LM guide and box guide to ensure optimum conditions according to machining characteristics

Servomotor directly coupled to the X / Z axis

The X / Z axis is directly connected to an extremely reliable digital servomotor to provide high rigidity and minimal thermal displacement.

Increase the distance between the guides

Increasing the distances between the guides allows an optimal axial force, leading to a stable supply in operations.

X / Z axis guide width

Increasing the width of the X / Z guides increases the stability of fast races.

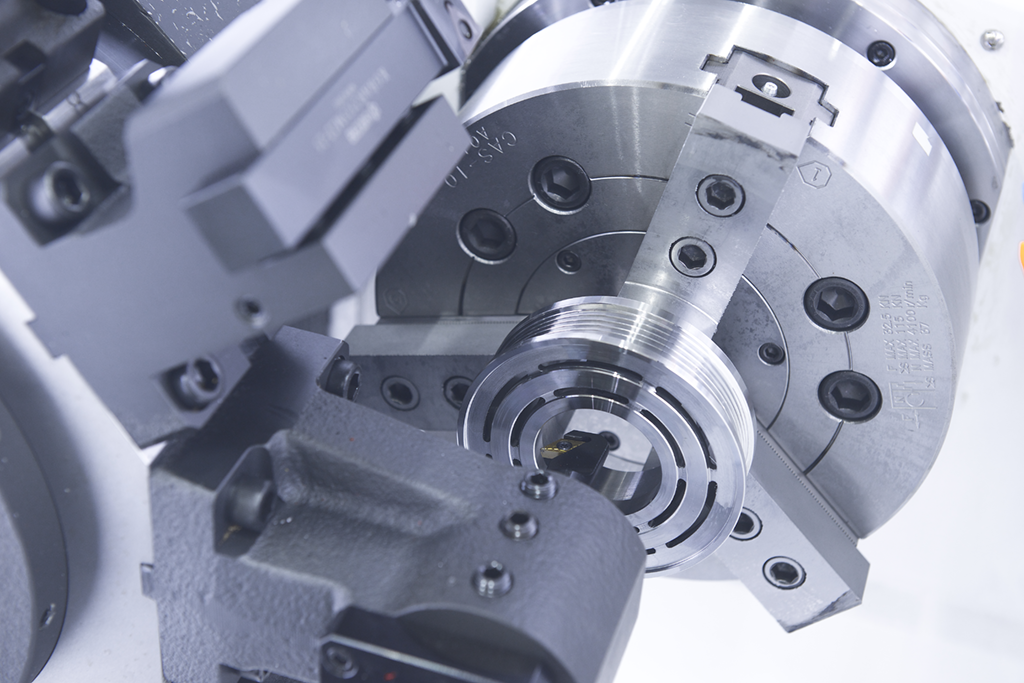

Spindle

Spindle for Heavy Cutting

The spindle has the highest speed and torque in its class, which provides high performance during high speed/heavy duty cutting. Also the spindle is designed with [Ø110 (Ø4.3″)] size P4 angular contact ball bearings to minimize thermal displacement and increase accuracy.

C-Axis Control (“M” Type)

C-axis of LF2600M II can be controlled to 0.001° which makes it possible to process various shapes.

Spindle Processing Flow

- Parts requiring secondary operations are transferredfrom Z1 spindle to Z2 spindle

- Same parts can be processed simultaneously by utilizingboth spindles of Z1/Z2-axis with same parts.03

- Different parts can be processed simultaneously byutilizing both spindles of Z1/Z2-axis with various parts.

Turret

Servo Turret

The turret of LF-II Series is applied with high performance AC servo motor, improving machining reliability. 3-piece coupling shows excellent performance in indexing. Moreover, powerful hydraulic hydraulic tool clamping minimizes tool tip deviation caused by load.

BMT55 (LF2100M / 2600M)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

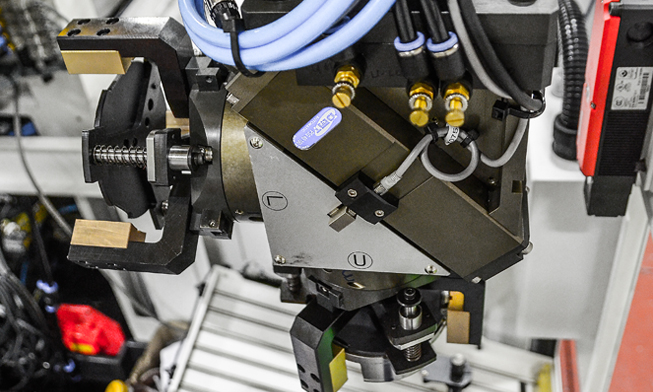

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

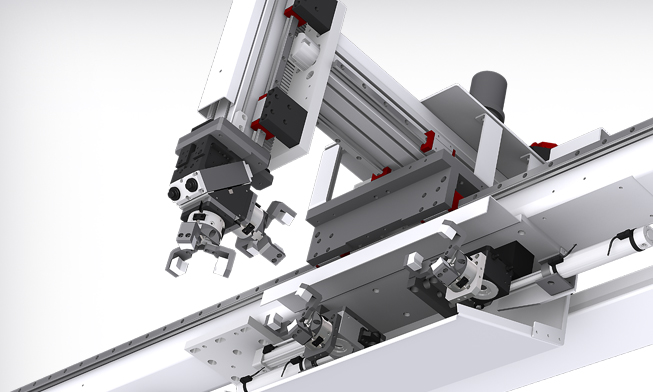

Configure automation to improve productivity

Gantry loader transfers raw material from in-stocker to machine

automatically, starting machining process. Gantry automation

provides good equipment access during operation and easy work monitoring, program modification and maintenance. In addition, small installation area facilitates optimized factory layout

Gantry automation provides good access to equipment during operation and easy monitoring of program processing, modification and maintenance. In addition, the small footprint facilitates the optimized appearance of the factory.

Technical Specifications LF2600II

| Max Turning Dia [mm] | 360 |

| Max Turning Length [mm] | 200 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 254/140 |

| Travel (X/Y) [mm] | 190/200 |

| Rapid Travel (X/Y) [mm] | 24/24 |

| Slide Type [tip] | Box |

| No. of Tools | 2 x 10 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | – |

Technical Specifications LF2600Quick II

| Max Turning Dia [mm] | 360 |

| Max Turning Length [mm] | 200 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 254/140 |

| Travel (X/Y) [mm] | 190/200 |

| Rapid Travel (X/Y) [mm] | 24/36 |

| Slide Type [tip] | Box |

| No. of Tools | 2 x 10 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | 5,000 |

Technical Specifications LF2600M II

| Max Turning Dia [mm] | 360 |

| Max Turning Length [mm] | 200 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 254/140 |

| Travel (X/Y) [mm] | 190/200 |

| Rapid Travel (X/Y) [mm] | 24/24 |

| Slide Type [tip] | Box |

| No. of Tools | 2 x 10 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | 5,000 |

Technical Specifications LF2600MQuick II

| Max Turning Dia [mm] | 360 |

| Max Turning Length [mm] | 200 |

| Driving Method | Belt |

| Chuck Size [inch/mm] | 10″/254 |

| Spindle RPM [rot/min] | 3,500 |

| Spindle Output [kW] | 15/11 |

| Spindle Torque [Nm] | 254/140 |

| Travel (X/Y) [mm] | 190/200 |

| Rapid Travel (X/Y) [mm] | 24/36 |

| Slide Type [tip] | Box |

| No. of Tools | 2 x 10 |

| Tool Size [mm] | 25/40 |

| Milling Tool Speed [rot/min] | 5,000 |

SImilar Products

Resource External Links