KF760BM

The KF760BM mold machining center is a 3-axis rigid guideway CNC machine with high mass and cutting speed ideal for the mold industry.

- Built-in spindle for a high-quality mold processing

- Excellent vibration absorption through box guideways in all axes

- Decrease of travel load with semi-air-floating slide way

- Prevent vibration fundamentally by seperated column and magazine

- Mold pacakage for precise machining (option)

Structure

Optimal Structural Analysis

KF760BM is designed to have optimal structure through Hyundai WIA’s unique structural analysis. In particular, enhancement of bed and column’s rigidity makes excellent performance even in heavy duty cutting.

We enhanced the rigidity of bed and column compared to the previous model for the better absorption of vibration. In particular, this exhibits the optimal performance for mold machining through increased ribs and additional weight based on unique interpretation technique of Hyundai Wia.

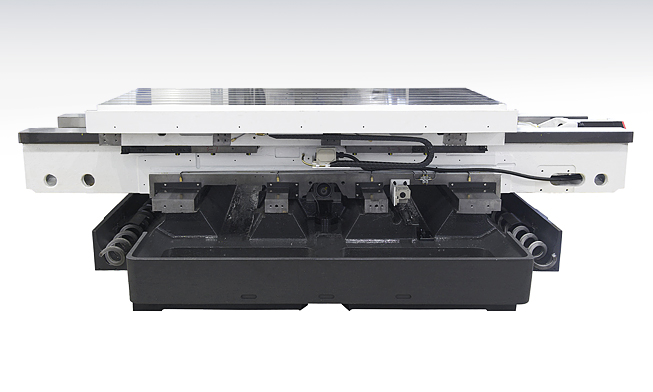

Work table

Compared to competitive machines, the KF760BM/960BM has a large working capacity to make setup easier and provide convenience to the operator.

NC Rotary Table

The NCRT makes it possible to machine up to 5-axis. Various

types of products can be machined.

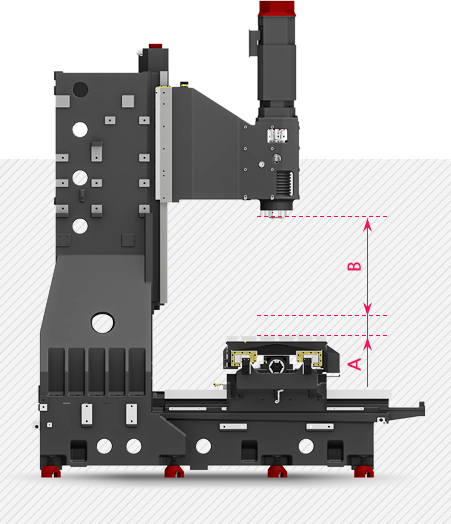

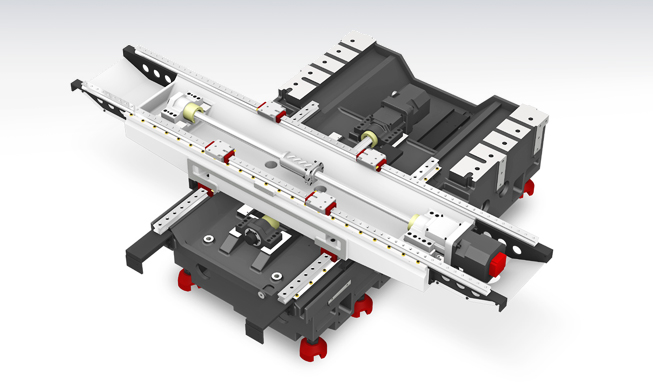

Guideway

All Axes Box Guideway

Box guideways effectively offset vibration enabling the machining of high precision products. The travel load is spread evenly on the surface of guideways. This enhances stability and rigidity allowing high performance heavy duty cutting.

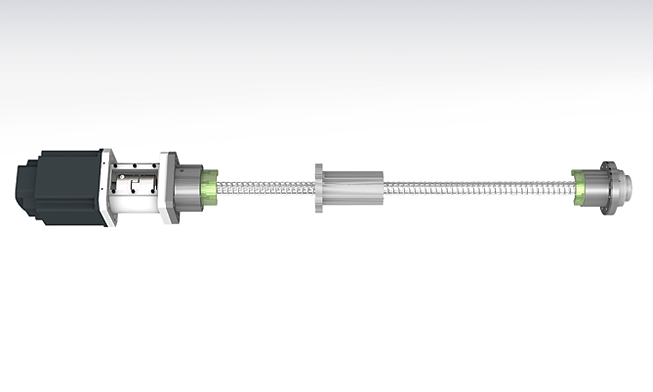

Double anchored ball screw

The pretensioned ball screw minimizes the expansion and contraction according to the heat and further reinforces the rigidity by the double anchor support method. In addition, the coupling of the ballscrews and the highly reliable digital servo motors are connected by metal plate couplings, to reduce coupling breakage and backlash.

Air Semi-Rising Slideway

By applying the air semi-rising slideways, the load on the X/Z-axis slideway is decreased. Therefore, positioning and repeatability accuracy can be maintained for a long time

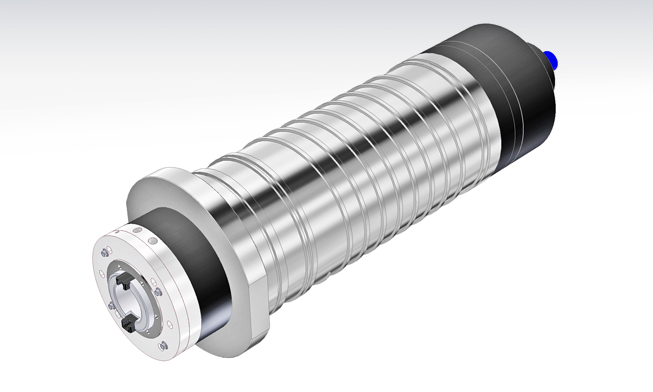

Spindle

High-precision Built-in Spindle

By using ultra precision angular ball bearings, fast acceleration and deceleration of the main spindle is achieved. The spindle head is designed to minimize the heat displacement of main spindle, and with the use of hydraulic Power tool lock system, the machining stability has increased.

Head Body Weight Reduction

Especially, over-hang problem is decreased due to weight reduction (10%) of main spindle compare to the previous model to achieve high-quality mold machining.

Spindle Cooling

The spindle cooling system minimizes thermal displacement which can happen during lengthy machining operations, and offers continued accuracy based on the thermal stability.

Through Spindle Coolant

Through Spindle Coolant is exceedingly useful when drilling deep

holes. It helps increase the lifetime of the tool, while decreasing

cycle time.

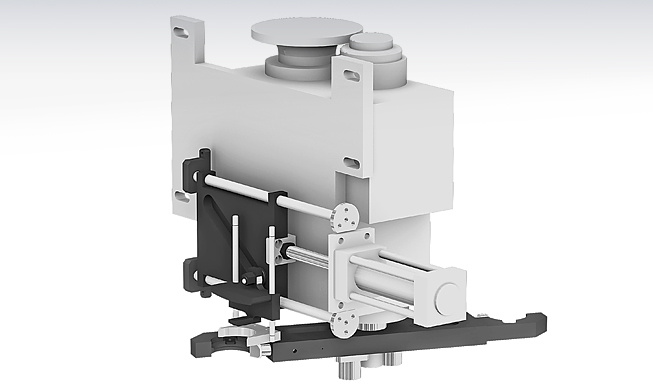

ATC & Magazine

Magazine Separated Brackets

Magazine of KF760BM is separated from the main column to

aviod magazine vibration which can affect precise mold machining.

KF760BM provides a tool magazine of 30 tools as standard. 40 tools are provided as an option. Also, ATC with high precision CAM provides fast and accurate tool change, reducing non-cutting time.

Technical Specifications KF760BM

| Table Size [mm] | 1800×700 |

| Max. Load Capacity [kg] | 2,000 |

| Spindle Driving Method | Built in |

| Spindle Taper | BBT50 |

| Spindle RPM [r/min] | 12,000 |

| Spindle Power [kW] | 30/25 |

| Spindle Torque [Nm] | 420/238 |

| Travel(X/Y/Z) mm | 1550/760/720 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 16/16/12 |

| Slide Type | BOX |

| No. of Tools | 30 |

| Tool Change Time (Chip To Chip) [sec] | 8.5 |