Hi-MOLD550/5A

Hi-MOLD550/5A 5-axis vertical center for high-quality mold processing with stable structure and integrated main spindle.

Hi-MOLD/5A Series Vertical Machining Centers, designed by Hyundai WIA with years of experience and cutting-edge technology, ensure the performance requirements of the mold industry. In addition, the 5-axis vertical center Hi-MOLD550/5A Hi-MOLD560 / 5A and Hi-MOLD750 / 5A can process products of various complex shapes on 5 axes.

- Very reliable wall type structure

- Very precise main spindles with ultra-precise angular bearings

- Built-in ultra-high speed main spindle (40,000 rpm) for the best mold quality (Opt.)

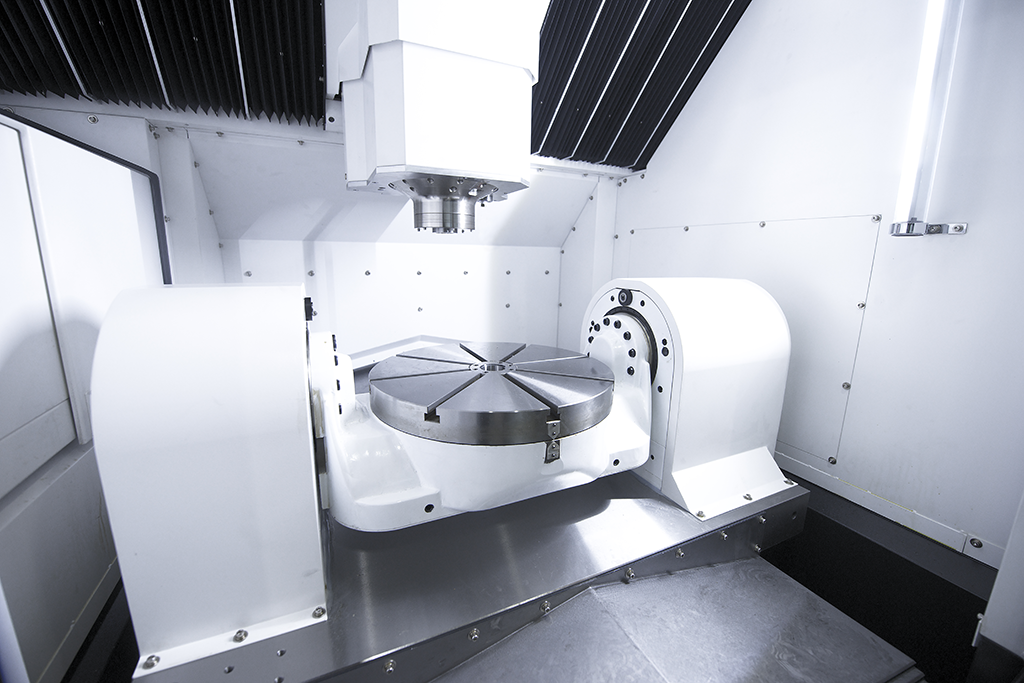

- Built-in 5-axis table to meet various processing needs (Hi-MOLD560 / 5A)

- The Hyundai WIA mold package provides optimal machining of mold parts

- The latest SIEMENS 840D controller for various software needs

Rigid structure

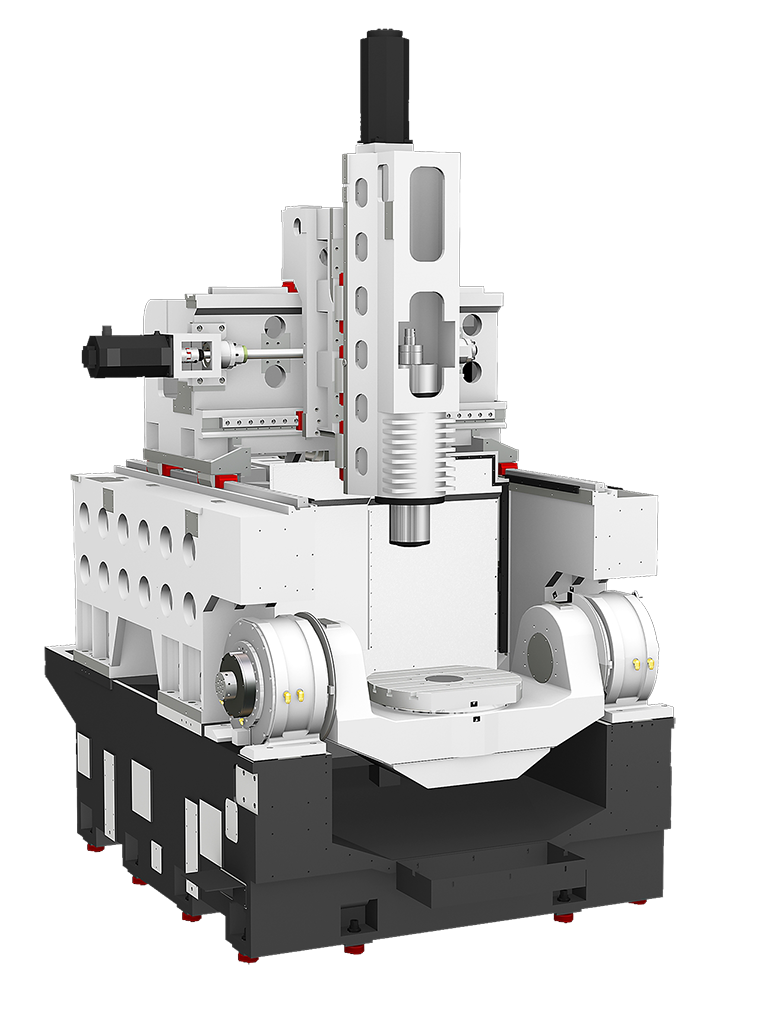

Double column type structure

The Hi-MOLD550/5A 5-axis vertical center is built on a double column structure frame. The biggest benefit of the double column machining center is increased rigidity and decreased heat generation. Therefore, it keeps the accuracy and repeatability at the highest levels.

Step Type Column Structure

Since the X-axis cross beam of the column has incorporated a “step” type design, the load occurring at the front during machining has been reduced.

Bed with X structure type

Hi-MOLD550/5A 5-Axis Vertical Center is designed with an extremely rigid X-type ribbed structure, which shows the best performance in high-quality mold processing. It can also provide strong rigid cutting and high precision machining due to excellent vibration absorption.

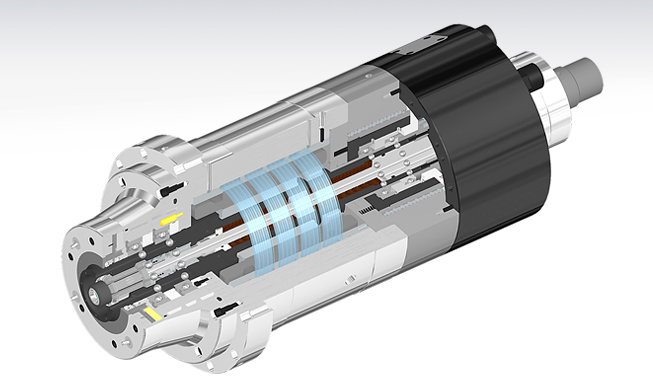

Integrated main spindle

The integrated shaft is designed to reduce vibration and heat, as well as provide quick acceleration / deceleration. Stable accuracy is maintained even in high-speed and intensive operations.

Main spindle cooling

The spindle cooling system reduces thermal distortion that can occur during extended machining and provides continuous accuracy based on thermal stability.

Coolant through spindle (20/30/70 bar)

Liquid cooling through the spindle is extremely useful when machining deep bores. It helps increase tool life while reducing machining cycle time.

Video machining Hi-MOLD750/5A

Technical specifications Hi-MOLD550/5A

| Table Size [mm] | Ø500×270 |

| Max. Load Capacity [kgf] | 250 |

| Spindle Driving Method | Build In |

| Spindle Taper | HSK-A63 |

| Spindle RPM [rot/min] | 24,000 |

| Spindle Power [kW] | 33/25 |

| Spindle Torque [Nm] | 96/72.5 |

| Travel (X,Y,Z) [mm] | 1,000(+350 ATC) /560/450 |

| Rapid Feed Rate (X/Y/Z) [m/min] | X50/Y50/Z50 |

| Slide Type [tip] | LM |

| No. of Tools | 24 |

| Tool Change Time (Chip To Chip) [sec] | 5.5 |