SE2000PA | SE2000PC

- 45° slanted one-piece rigid bed structure

- Minimal thermal distortion

- Machine structure designed to maximize productivity

- Best in class rapid traverse rate : 36m/min (SE2000A/MA/C/MC)

- The most reliable high speed servo turret : 0.1sec/step

- Box Guideways to handle heavy cutting (SE2000PA/PC)

- Compact design, able to install within a limited space.

- Ergonomic design allows convenient access to chuck and tool

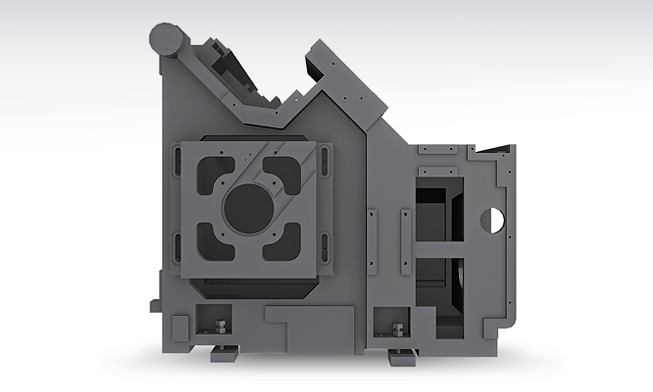

High Rigidity, One-Piece Structure

The SE2000P/PC CNC lathe are designed with a 45° slanted bed combined with square type and tube type rib structure. This special design enhances rigidity and vibration absorbing capability, allowing powerful cutting with high precision.

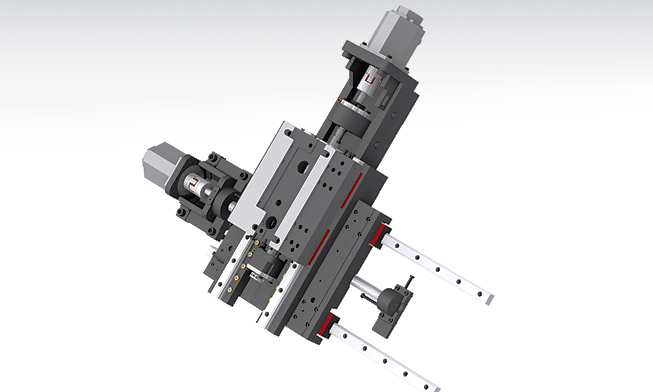

Guideway

Box Guideway

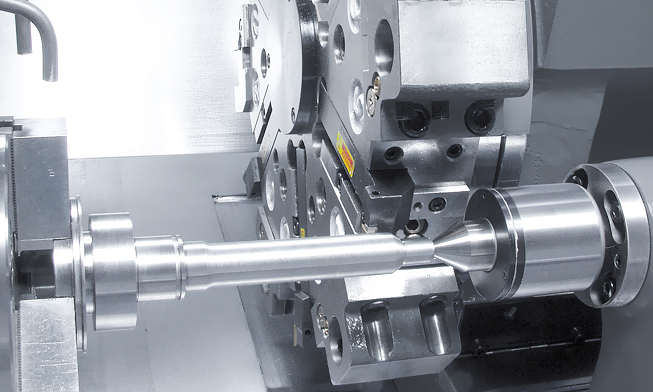

All axes of SE2000P/PC CNC lathe are designed with Box Guideways for better travel ability. Box Guideways show great performance in offsetting vibrations caused by heavy duty cutting

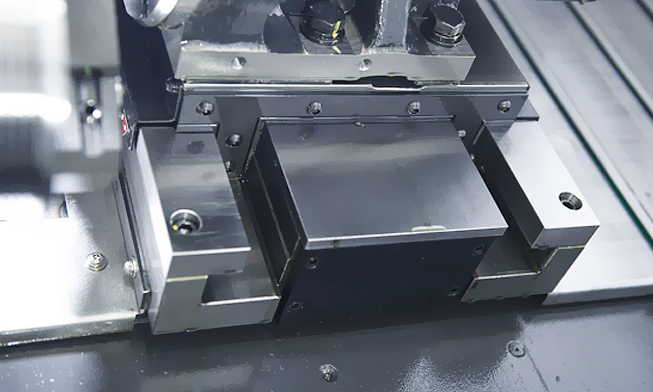

Ball Screw

Travel is stabilized by fastening both ends of the ball screw using the

double anchored method. In particular, a large diameter ball screw with proper preload reinforces sturdiness and resistance to thermal

displacement.

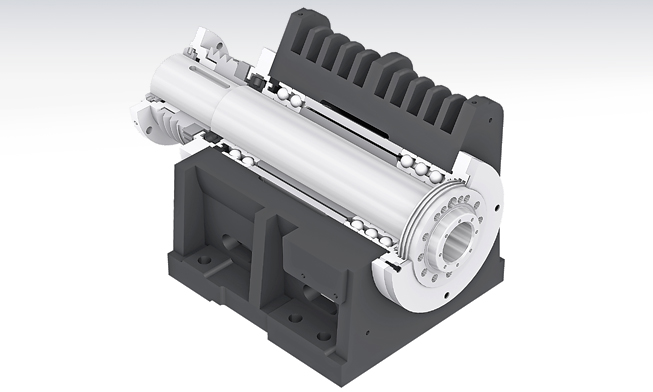

Spindle

The main spindle is designed with the same structure often found in larger sized machines. The combination of taper roller bearings and angular contact ball bearings leads to excellent heavy duty cutting performance.

Also, machining performance is enhanced by applying ribstar belt to minimize noise and belt slipping problems. The spindle is designed with a Labyrinth structure to minimize possible bearing damage from coolant and to improve machining stability.

De asemenea, performanța de prelucrare este îmbunătățită prin aplicarea centurii ribstar pentru a minimiza zgomotul și problemele de alunecare a centurii. Fusul este proiectat cu o structură Labyrinth pentru a minimiza posibilele deteriorări ale lagărului cauzate de lichidul de răcire și pentru a îmbunătăți stabilitatea la prelucrare.

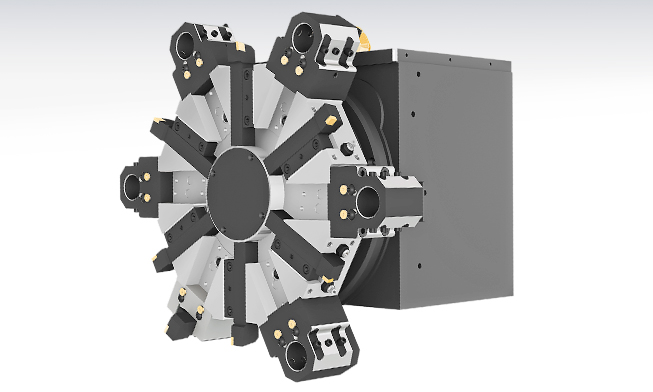

Servo Turret

The turret of SE2000PA/PC is applied with high performance AC servo motor, improving machining reliability. 3-piece coupling shows excellent performance in indexing. Powerful hydraulic tool clamping minimizes tool tip deviation caused by load.

Tail Stock

Tailstock enables stable machining of high quality products where quill

travels up to 80mm.

Fanuc Smart Plus controller

Technical specifications SE2000PA

| Max Turning Dia [mm] | 350 |

| Max Turning Length [mm] | 280 |

| Driving Method [tip antrenare] | Curea |

| Chuck Size [inch/mm] | 6″/152.4 |

| Spindle RPM [rot/min] | 6,000 |

| Spindle Output [kW] | 11/15 |

| Spindle Torque [Nm] | 52.5/92.5 |

| Travel (X,Y) [mm] | 210/330 |

| Rapid Travel [m/min] | 24/24 |

| Slide Type [tip] | Box |

| No. of Tools | 12 |

| Tool Size [mm] | 25/32 |

Technical specifications SE2000PC

| Max Turning Dia [mm] | 350 |

| Max Turning Length [mm] | 270 |

| Driving Method [tip antrenare] | Curea |

| Chuck Size [inch/mm] | 8″/203,2 |

| Spindle RPM [rot/min] | 4,000 |

| Spindle Output [kW] | 11/15 |

| Spindle Torque [Nm] | 92/167 |

| Travel (X,Y) [mm] | 210/330 |

| Rapid Travel [m/min] | 24/24 |

| Slide Type [tip] | Box |

| No. of Tools | 12 |

| Tool Size [mm] | 25/40 |