LV8500R/L | LV8500RM/LM

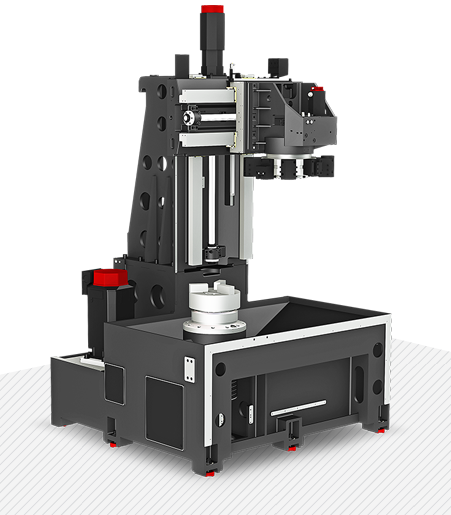

Flexible, Productive Automation System Vertical Turning Center

The CNC Turning Center LV8500 Series, designed by Hyundai WIA with years of expertise and the latest technology, is designed to maximize productivity by high speed and accurate performance.

- “Right” and “Left” structure for practical automation construction

- Vertical cnc lathe LV8500 have a Stable spindle structure with excellent heavy duty cutting ability

- 2 step pressure chucking system (Opt.)

- BMT turret applied for heavy duty cutting (Mill turret models)

- Designed for optimal chip disposal

Structural Design

High-Precision Structure

The LV8500 Series consists of Left and Right machine configuration, allowing for more efficient automation options. Oil and Air devices are located in front of the machine for easy repair and maintenance.

Front Operation Structure

The power supply, hydraulic device and lubrication device are all designed to be accessed from the front, which leads to user comfort.

Guideway

Box Guideway

All axes of the LV8500 Series feature box guideways. Box guideways provide long term rigidity and accuracy even during heavy duty operations.

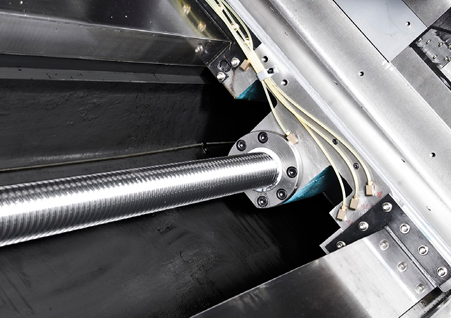

Ball Screw

Large diameter ball screws with preloading prevent deformation due to heat. Also double-anchor suppport method improves rigidity.

Frame

Step frame structure

For the LV8500 vertical lathe, the main movement of the column is adjusted in steps so that the load generated in front during the processing operations is reduced to a minimum. Also, by optimizing the weight of the column, the stability of the feed is improved.

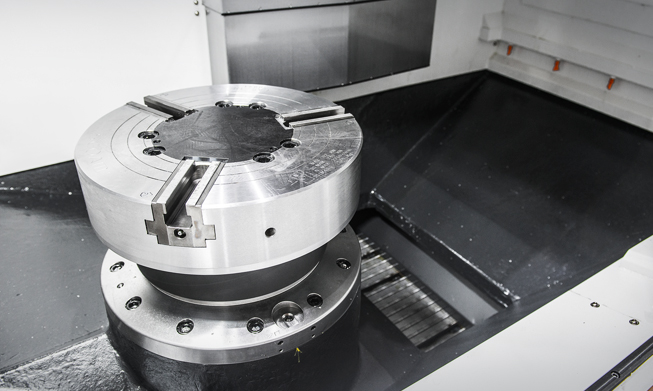

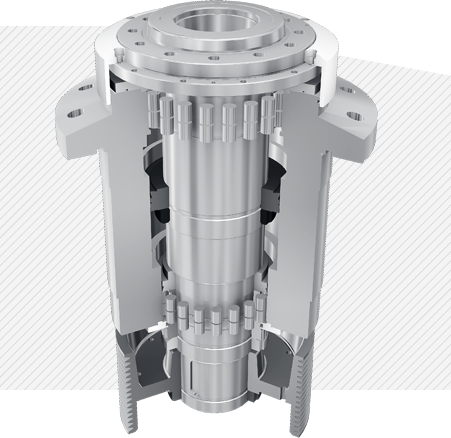

Spindle

Spindle for Heavy Cutting

The use of both cylindrical roller bearings and angular contact bearings provide high speed and rigidity. This enables machining of heavy workpieces. Also, LV8500 Series is with a gear box type spindle (Option) ,which provides high torque at low rpm and stability at high rpm.

C-Axis Control (‘M’ Type)

The C-axis is capable of 0.001° control when milling turret is applied. Machining capability is strengthened with turning and milling operations.

LPS (Linear Position Sensor)

The LV8500 Series is incorporated with a protection device to keep chips and other foreign materials from entering the main spindle, ensuring long term high precision performance.

Chip Influx Protection

Protection against chipping

The LV series is incorporated with a protection device to prevent the penetration of chips and other foreign materials into the main shaft, ensuring long-term high-precision performance.

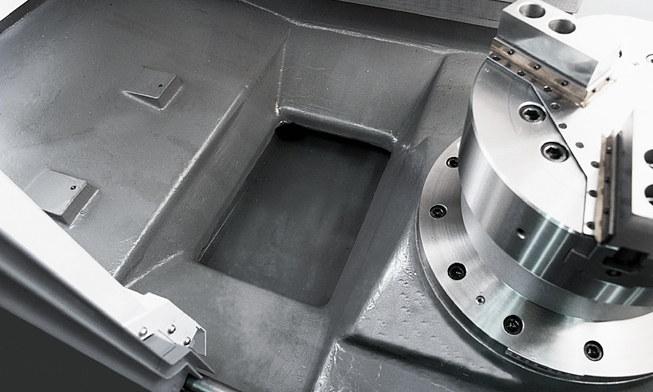

Exhaust structure

The design of the sloping gutter improves the flow of chips and the elimination of coolants by reducing thermal deformation.

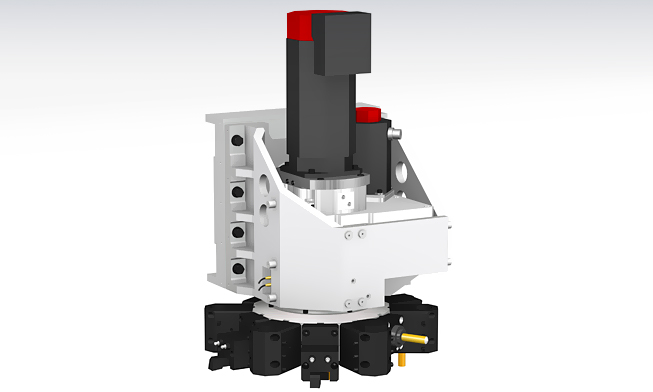

Servo Turret

The LV8500 Series’ machining reliability is enhanced by incorporating a high performance AC servo motor to the turret drive mechanism. Also, the turrets are installed with 3 piece couplings to improve indexing accuracy. Powerful hydraulic tool clamping exhibits great heavy duty machining performance by minimizing tool tip deviation due to work load.

Milling turret

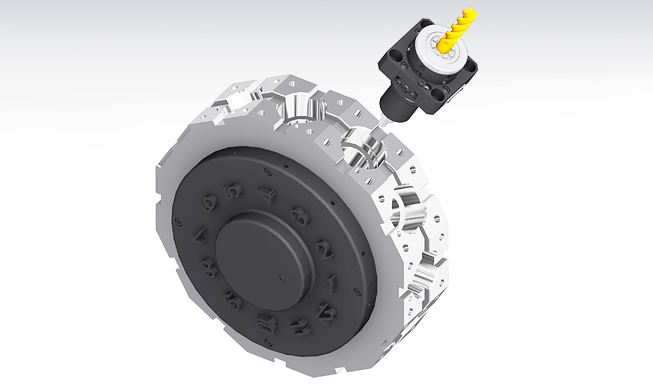

BMT Turret (‘M’ Type)

The BMT turret secures the tool with four bolts and key on the tool mounting surface of the turret, making it possible to powerfully fix the tool, ensuring high reliability in rigidity and precision.

Mill Tool Holder

Machining capability has increased with the addition of straight milling head tool holder, which can machine workpieces from the side, and angular milling head tool holder, which can perform I.D. operations.

Technical Specification LV8500R/L

| Max Turning Dia. [mm] | 850 |

| Max Turning Length [mm] | 800 |

| Driving Method [tip antrenare] | Belt |

| Chuck Size[inch/mm] | 18″/457,2 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 22/18.5 |

| Spindle Torque [Nm] | 1,660/986 |

| Travel (X,Y) [mm] | 465/800 |

| Rapid Travel [m/min] | 20/20 |

| Slide Type [tip] | Box |

| No. of Tools | 12 |

| Tool Size [mm] | 32/63 |

| Milling Tool Speed [rot/min] | – |

Technical Specification LV8500RM/LM

| Max Turning Dia. [mm] | 850 |

| Max Turning Length [mm] | 800 |

| Driving Method [tip antrenare] | Belt |

| Chuck Size [inch/mm] | 18″/457,2 |

| Spindle RPM [rot/min] | 2,000 |

| Spindle Output [kW] | 37/22 |

| Spindle Torque [Nm] | 1,660/986 |

| Travel (X,Y) [mm] | 465/800 |

| Rapid Travel [m/min] | 20/20 |

| Slide Type [tip] | Box |

| No. of Tools | 12 |

| Tool Size [mm] | 32/63 |

| Milling Tool Speed [rot/min] | 4,000 |