i-CUT4000/4500

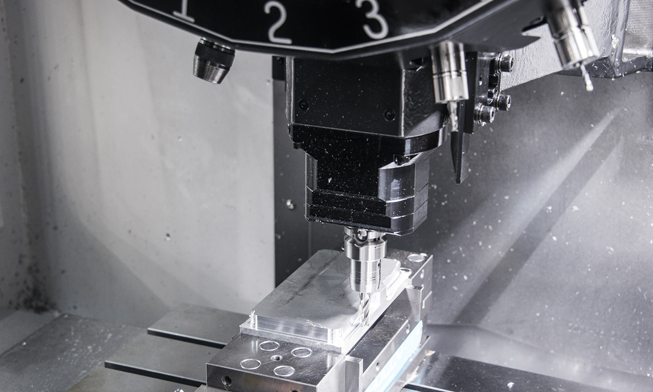

The Tapping Center I-Cut 4000, designed by HYUNDAI WIA with years of experience and state-of-the-art technology, maximizes productivity while maintaining rigidity and accuracy.

Tapping Center I-Cut 4000 series is designed by Hyundai WIA with years of experience and state-of-the-art technology, maximizing productivity while maintaining the rigidity and accuracy of processing.

- Realization of high-precision machining through improvement of spindle quality

- Max. 24,000r/min Direct Spindle

- High performance double seal type LM guide applied

- Best-in-class tool change time (C-C : 1.8 sec)

- Twin arm type ATC for automation system (Option)

- Shower coolant & bed coolant standard application

Compact Design

Weight reduction by structural analysis

Compared to the previous model, the structural rigidity has increased, while the weight of the car has been lightened simultaneously by the unique technique of Hyundai WIA.

Linear guides

High-speed fast travel is achieved by using LM (Linear Motion) linear guides. This reduces cutting time and decreases processing time for higher productivity.

The double anchored and prestressed design offers remarkable positioning and repeatability with minimal thermal increase. The ball screws are connected directly to the actuator to eliminate leaks.

High-performance Spindle

Direct Drive

The main shaft is designed with angular contact ball bearings to increase rigidity, prevent thermal displacement.

Rigid threading

The rigid threading function allows fast and accurate threading. It also improves tool accuracy and tool life.

Spindle coolant

The shaft coolant is extremely useful for drilling deep holes. It helps to increase the life of the instrument, while reducing the cycle time.

Automatic tool magazine

Magazine

Unlike the previous models that featured a 14-tool magazine, the i-CUT4000/4500 adopted a 21-tool magazine as standard to expand the

tooling range.

Servo ATC

Servo motor is applied on the ATC to reduce tool change time. Also,

accurate tool positioning control increases cutting stability

FANUC 0i Plus Series

- The FANUC 0i-F Plus series CNC offers a simple, cost-optimized solution for most general processing applications.

- Ready to use, it boasts state-of-the-art hardware and a complete standard software package for most turning and milling processes.

- Customization features are already included and provide an easy way to create application-tailored HMI interfaces.

- The 0i-F Plus series is also fully compatible with older FANUC 0 and 0i CNCs and has the same programming as more advanced FANUC controls.

- The advantage is that existing programs can be used immediately and that new programs can be developed without the need for costly layoffs.

- Offering the high performance of FANUC servo technology, this CNC also offers the same easy-to-use comfort across the range.

Video processing i-CUT400TD

Technical Specification i-CUT4000

| Table Size[mm] | 650×400 |

| Max. Load Capacity [kg] | 300 |

| Spindle Driving Method [tip] | Direct Drive |

| Spindle Taper [tip] | BBT30 |

| Spindle RPM[r/min] | 12,000 |

| Spindle Power [kW] | 13/3.7 |

| Spindle Torque [Nm] | 82.7/23.5 |

| Travel (X,Y,Z) [mm] | 550/400/300 |

| Rapid Feed Rate [m/min] | X56/Y56/Z56 |

| Slide Type [tip] | Liniare |

| No. of Tools | 21 |

| Tool Change Time (Chip To Chip) [sec] | 1.8 |

Technical Specification i-CUT4500

| Table Size [mm] | 800×450 |

| Max. Load Capacity [kg] | 300 |

| Spindle Driving Method [tip] | Direct Drive |

| Spindle Taper [tip] | BBT30 |

| Spindle RPM [r/min] | 12,000 |

| Spindle Power [kW] | 13/3.7 |

| Spindle Torque [Nm] | 82.7/23.5 |

| Travel (X,Y,Z) [mm] | 700/450/300 |

| Rapid Feed Rate [m/min] | X56/Y56/Z56 |

| Slide Type [tip] | Liniare |

| No. of Tools | 21 |

| Tool Change Time (Chip To Chip) [sec] | 1.8 |