KF3500/5A

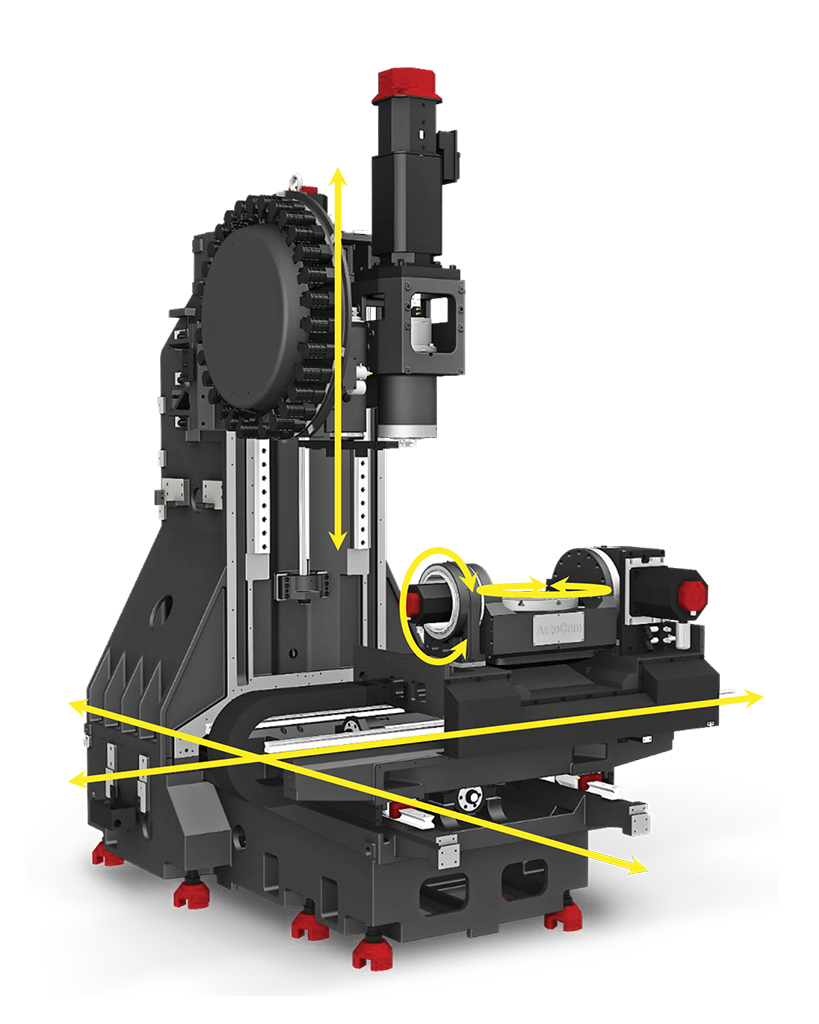

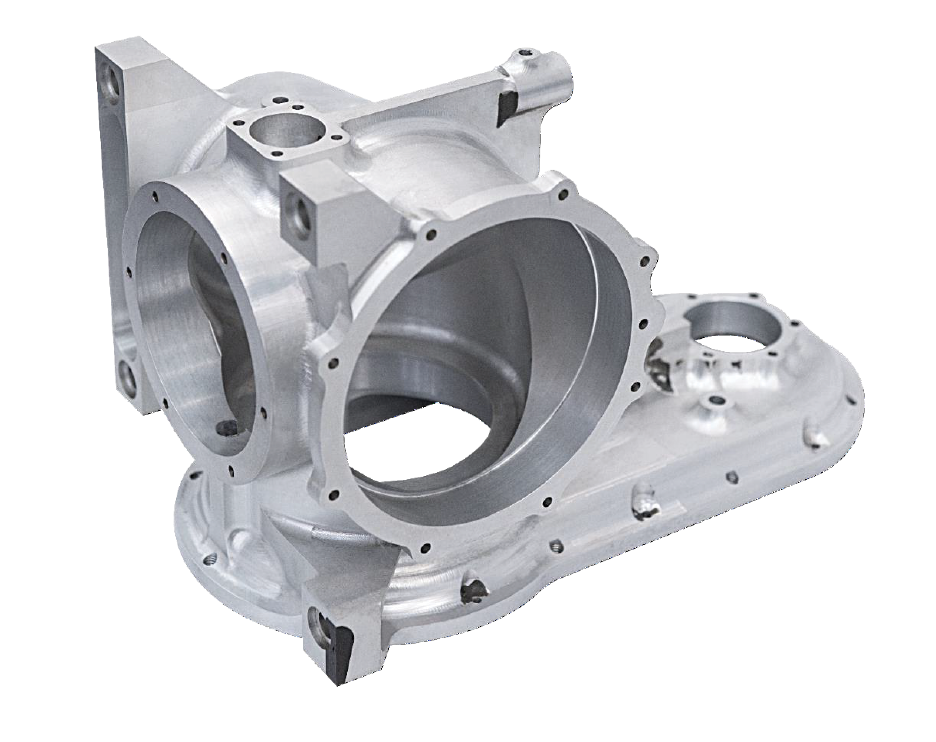

Best Performance in the Class & Vertical Machining Center for 5-axis Machining KF3500/5A developed with application of accumulative know-how and new technology of Hyundai Wia is a next-generation machining center featuring optimal performance in complex form machining.

- A/C axis high rigidity roller gear cam drive method applied

- Vastly superior in power delivery efficiency and strength compared to worm gear of other companies

- Rapid traverse rate of A axis 30rpm and C axis 40rpm

- High-speed 12,000rpm spindle (Opt. 15,000/20,000rpm)

- High-speed tool change time (C-C) 3.4 sec

- High-speed roller type LM guide in all axes

- Convenient work loading through crane with top cover featuring open structure

- Compact design suitable for installation in restricted space (6.5㎡)

- Applying the latest controller of FANUC 0i PLUS

Work table

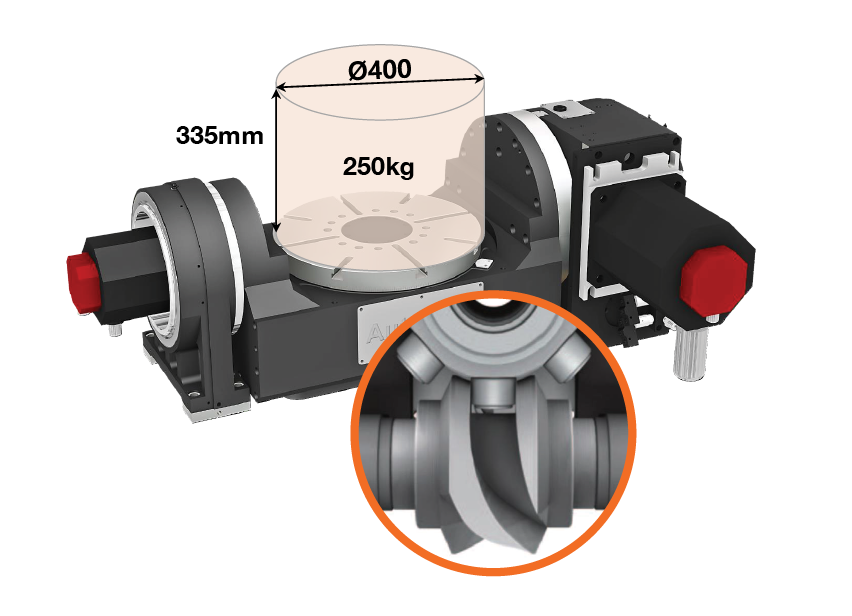

5-axis Tilting Rotary Table

The 5-axis tilting rotary table allows users to produce a wide range of complicated work pieces. The ‘C’ axis has full 360° rotation and the ‘A’ axis has 150° rotation.

Roller Gear Cam

KF3500/5A developed with application of accumulative knowhow and new technology of Hyundai Wia is a next-generation machining center featuring optimal performance in complex form machining. Also, it has superb precision and durability while also being excellent for five-axis machining with less power loss even at high-speed rotation (Superior power delivery efficiency and strength compared to worm gear table of other companies).

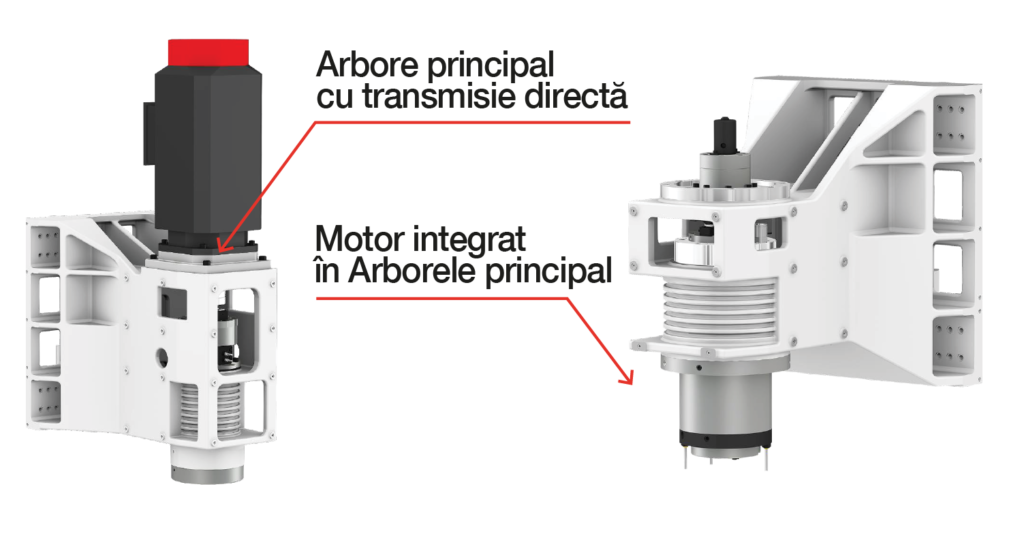

Spindle

Direct Driven Spindle

The directly coupled spindle at a maximum revolution of 12,000rpm [Opt.15,000rpm], allows high-speed processing. Additionally, the large diameter and the thickness of the spindle add to the stability of the machine.

Built-in Spindle

The built-in spindle minimizes spindle vibration, enabling outstanding performance in a high-precision cutting environment such as complex shaped work-piece.

Through Spindle Coolant

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time.

High-Speed Roller LM Guideway

By applying an roller LM guide structure with high speed and rigidity, a rapid traverse rate of 36m/min is achieved based on the X/Y axis.

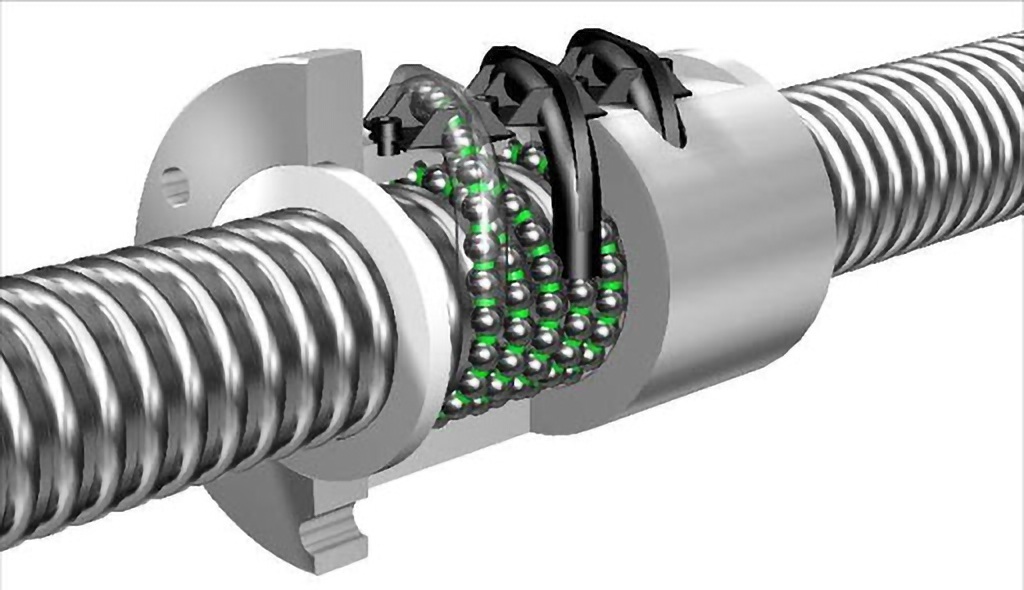

Ball Screw

The pretensioned ball screw minimizes the expansion and contraction according to the heat and further reinforces the rigidity by the double anchor support method.

High Speed ATC

Position control through twin arm ATC on servo motors has been improved drastically. In addition, tool exchanging has become easier, reducing specific cutting time tremendously

Magazine

The tool magazine holds 30 tools as standard and 40 tools as an option. Due to the wider selection of tools and the random tool selection method, tool change time has improved.

Video machining KF3500/5A

Technical Specifications KF3500/5A

| Table Size [mm] | 350 |

| Max. Load Capacity [kg] | 250 |

| Spindle Driving Method | Direct |

| Spindle Taper | BBT40 |

| Spindle RPM [r/min] | 12,000 |

| Spindle Power [kW] | 18.5/11 |

| Spindle Torque [Nm] | 118/52.5 |

| Travel(X/Y/Z) mm | 600/655/500 |

| Rapid Feed Rate(X/Y/Z) [m/min] | 36/36/30 |

| Slide Type | LM |

| No. of Tools | 30 |

| Tool Change Time (Chip To Chip) [sec] | 3.4 |