KF6700BII | KF6700B/50II

The fastest and most versatile KF6700BII vertical center in high precision and rigid linear processing.

- High power/torque main spindle for superb heavy duty cutting

- Box guideways for exceptional traveling during heavy duty cutting

- Enhanced chip processing capabilities by applying the upper-type conveyor

- Various motors and columns provided for customized machining

- Vertical Center KF6700BII Improved user convenience by applying the latest controller of FANU

Structure

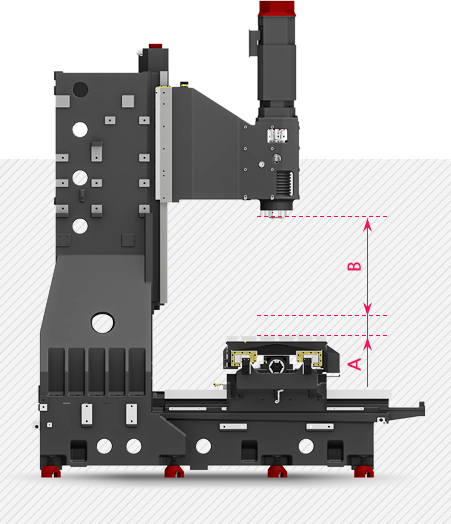

High-Rigidity Design For Column & Bed

The stable design of column assembly surface on bed top enables securing the fundamental rigidity of the structure

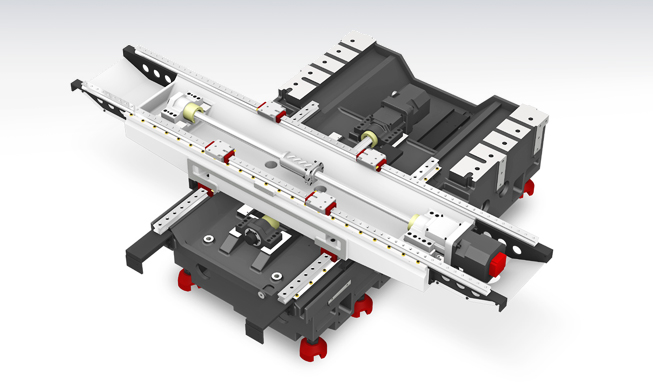

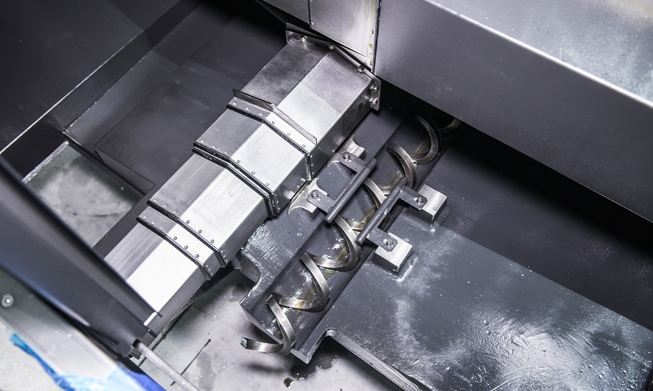

Guideway

The KF-B II Series are equipped with box guideways to enable

distributing its feeding force evenly to each slideway. It boasts excellent rigidity, a stable feed structure, and an increased box guide slideway, thus providing an excellent heavy-duty cutting performance.

Double Anchored Ball Screw

The pretensioned ball screw minimizes the expansion and contraction according to the heat and further reinforces the rigidity by the double anchor support method. In addition, the coupling of the ballscrews and the highly reliable digital servo motors are connected by metal plate

couplings, to reduce coupling breakage and backlash

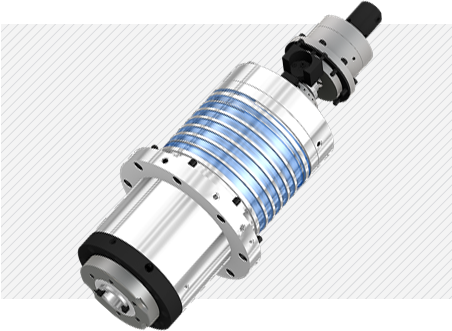

Spindle

Direct Driven Spindle

The directly coupled spindle at a maximum revolution of 12,000rpm, allows highspeed processing. Additionally, the large diameter and the thickness of the spindle add to the stability of the machine.

BBT40 coupling

The Big Plus shaft system (BBT40) ensures double contact between the shaft and the tool holder.

Spindle Cooling

The spindle cooling system minimizes thermal displacement which can happen during lengthy machining operations, and offers continued accuracy based on the thermal stability.

Through Spindle Coolant (20/30/70 bar)

Through Spindle Coolant is exceedingly useful when drilling deep holes. It helps increase the lifetime of the tool, while decreasing cycle time. The improved quality of rotary joint prevents oil leakage.

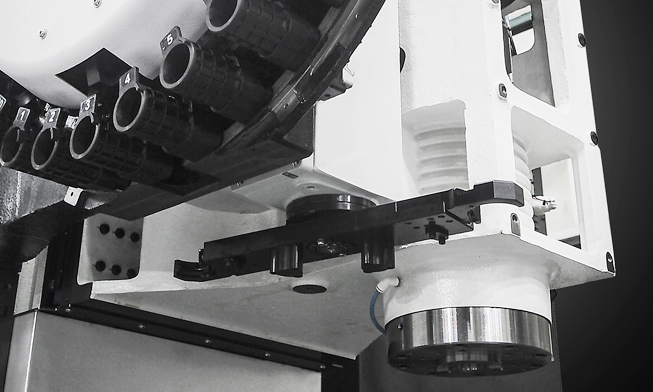

Tool Magazine

High Speed ATC

Position control through twin arm ATC on servo motors has been

improved drastically. In addition, tool exchanging has become easier, reducing specific cutting time tremendously. Position control on the Twin Arm ATC has improved drastically. The twin arm ATC enables faster tool change and increased productivity

Magazine

A magazine that can attach various tools between 24~40 EA was

adopted to increase the range of selection for machining tools, and the overall size of the magazine was reduced to reduce vibration during magazine rotation to improve surface finishing

Chip evacuation

Dual screw type chip conveyors are located at each side of the bed which makes it convenient to remove chips. The interior screw and the chip conveyor operate at the same time and can be controlled separately at the time of prior consultation.

(Three screws for rear-type conveyor: 2 sides + 1 front) Furthermore, chip disposal capability significantly has been improved due to optional bed-flushing coolant.

Technical SpecificationKF6700B II

| Table Size [mm] | 1,500×670 |

| Max. Load Capacity [kg] | 1,300 |

| Spindle Driving Method [tip] | Direct |

| Spindle Taper [tip] | BBT40 |

| Spindle RPM [r/min] | 8,000 |

| Spindle Power [kW] | 15/11 |

| Spindle Torque [Nm] | 286/143 |

| Travel (X,Y,Z) mm | 1,300/670/635 |

| Rapid Feed Rate (X/Y/Z) [m/min] | 30/30/24 |

| Slide Type [tip] | Box |

| No. of Tools | 30 |

| Tool Change Time (Chip To Chip) [sec] | 3.7 |

Technical SpecificationKF6700B/50 II

| Table Size [mm] | 1,500×670 |

| Max. Load Capacity [kg] | 1,300 |

| Spindle Driving Method [tip] | Direct |

| Spindle Taper [tip] | BBT40 |

| Spindle RPM [r/min] | 8,000 |

| Spindle Power [kW] | 15/11 |

| Spindle Torque [Nm] | 286/143 |

| Travel (X,Y,Z) mm | 1,300/670/635 |

| Rapid Feed Rate (X/Y/Z) [m/min] | 30/30/24 |

| Slide Type [tip] | Box |

| No. of Tools | 24 |

| Tool Change Time (Chip To Chip) [sec] | 5.5 |